“We bring specialized expertise to the sustainable PV industry, ensuring that every panel we process strengthens India’s circular economy.”

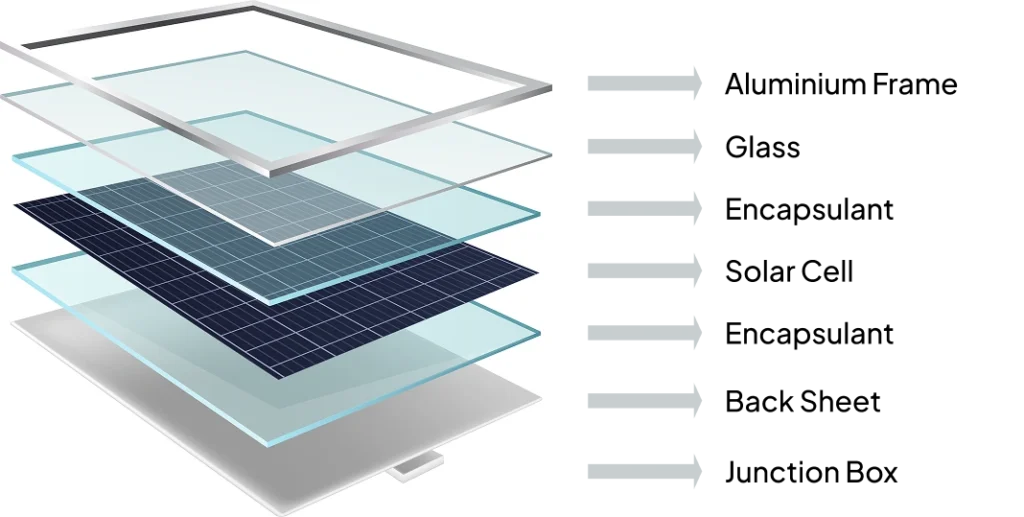

While manufacturing creates this waste, ReGen provides the solution by reclaiming the silicon from the finished cells at their end-of-life.

“The solar manufacturing process currently loses up to 30% of high-purity polysilicon as ‘kerf’ (sawing dust). At ReGen, we close this efficiency gap by reclaiming the high-value silicon embedded in end-of-life cells, returning it to the supply chain and reducing the energy-intensive demand for virgin silicon production.”

The diamond-wire sawing process used in photovoltaic manufacturing produces silicon wafers with thicknesses below 150 µm; however, it also generates large quantities of kerf—fine silicon particles dispersed in sawing slurry. Despite its high silicon purity, this kerf remains largely underutilized due to the lack of efficient recycling solutions.

Leveraging its strong background in silicon purification, ReGen has engineered advanced solutions to recover and remelt high-purity silicon from kerf waste streams. This innovation unlocks a sustainable source of silicon for photovoltaic manufacturing, reinforcing a circular and low-impact supply chain.

of high-purity polysilicon as ‘kerf’